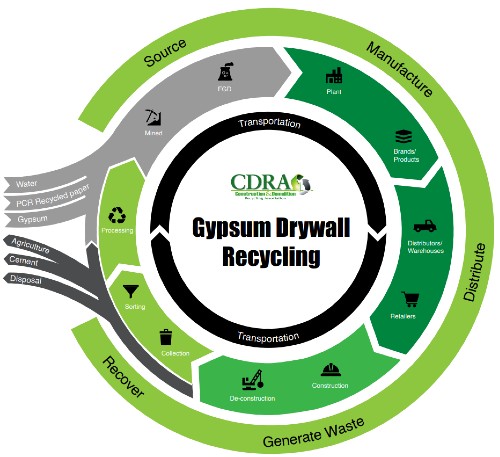

Gypsum Drywall To give you a basic overview of gypsum drywall recycling, we’ve compiled answers to commonly-asked questions about the process.

What is Gypsum Drywall?A description of gypsum drywall must first begin with a discussion of gypsum itself. Gypsum, a naturally occuring mineral, is composed of calcium sulfate (CaSO4) and water (H2O). Also referred to as hydrous calcium sulfate (CaSO4.2H2O), gypsum is mined from deposits formed by ancient seabeds as a raw material for many different manufacturing, industrial, and agricultural uses. Over 80% of the gypsum mined is used in manufactured products such as drywall. Gypsum possesses many attributes that make it an attractive construction material. Calcined gypsum can be wetted to form a paste that can be directly applied to a structure’s surface or that can be molded into a desired shape; the gypsum hardens upon drying. Gypsum is naturally fire resistant. Gypsum drywall, often referred to as gypsum wallboard or sheet rock, replaced gypsum plaster as the major material used for interior wall surfaces because of its ease of installation. Gypsum drywall consists of approximately 90% gypsum and 10% paper facing and backing. Drywall is manufactured by first calcining the gypsum, a process that heats the mineral to remove part of the water (resulting in CaSO4.1/2H2O). The stucco that is formed is then rehydrated by mixing with water, and the slurry created is spread onto a moving continuous sheet of paper and sandwiched between another layer of paper. This continuous sheet of wallboard is allowed to harden for several minutes, cut into panels and sent to a kiln for final drying. It is trimmed to the dimensions required, bundled, and is then ready for shipment. Drywall comes in many different types and sizes to meet specific construction needs. Can Gypsum Drywall be recycled?The mineral gypsum has many uses in today’s society. In addition to the manufacture of drywall for building construction, gypsum is also widely used as a soil amendment, in the production of cement, and as an ingredient in the manufacture of many types of commercial products. Since the gypsum makes up approximately 90% of the weight of a piece of drywall, if the gypsum can be recovered from the drywall, the majority of the material can be recycled. Scrap gypsum drywall is currently being recycled in several locations in North America. Examples include:

Despite its successful use in many locations, most drywall in North America is still disposed in landfills. Challenges to widespread recycling include collection and separation, low landfill disposal fees, and the need for more education of potential end users of the recycled material. For more information on how gypsum drywall can be recycled, see the Markets page. Can Gypsum Drywall create odor problems when disposed in landfills?When gypsum drywall is disposed in landfills, a series of biological and chemical reactions can occur that have the potential for adverse environmental impacts. When drywall in a landfill gets wet, some of the sulfate from the gypsum dissolves into the water. If this “leachate” reaches the groundwater, contamination with sulfate may result. The US federal secondary drinking water standard for sulfate is 250 mg/L. Concentrations above this level have been observed in the groundwater at unlined C&D debris landfills. The sulfate also contributes to the high total dissolved solids (TDS) concentrations observed in groundwater at many C&D debris landfills. Another issue results form the biological conversion of dissolved sulfate to hydrogen sulfide (H2S). H2S is a foul-smelling gas (rotten eggs). It is produced under wet, anaerobic conditions, such as those that often occur in landfills. The presence of organic matter such as yard trash or cardboard is needed for the microorganisms to thrive, but even the paper on the drywall itself provides enough organic matter for the biological reactions to proceed. H2S has been observed over a tremendously large concentration range at C&D debris landfills. The human nose can detect H2S concentrations at relatively low concentrations (250 ppm). Usually by the time the gas reaches the atmosphere, it is usually diluted to below most currently accepted safety concentrations. Landfill operators should exercise extreme caution, however, any time undiluted C&D debris landfill gases might come in contact with a worker (e.g. excavation activities, confined spaces). The odor problem alone has been enough to result in strict actions being required on the part of some landfill operators. Some C&D debris landfill operators have been required to install gas collection and recovery systems, and others have resorted to placing odor masking agents around their sites. In the Vancouver area, gypsum drywall was banned from disposal in landfills as a result of odor problems. Any comments regarding this website will be welcomed. Please feel free to contact us at [email protected]. More Information: |